We produce “filter press systems”, which are one of our areas of specialization, in short-time, with wide capacity range and various material choices.

Our company, in addition to TSEK, ISO 14001 Envi- ronmental Management System and OHSAS Certifi- cates, is accredited for ISO 9001-2000 Quality Mana- gement System.

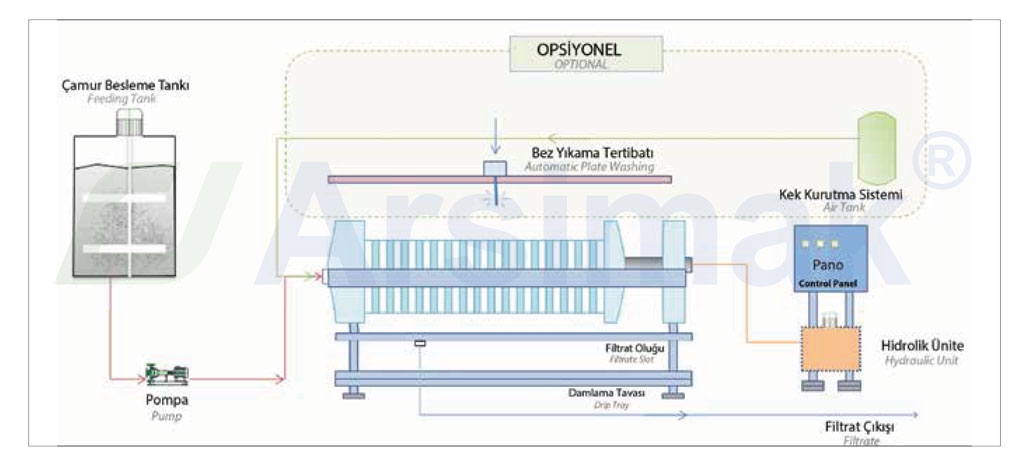

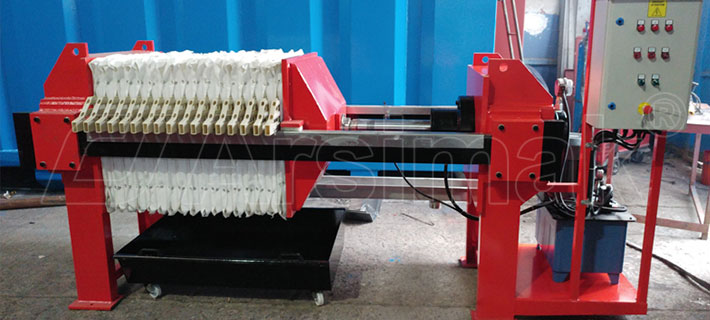

Filter Presses are dewatering equipments with the highest dewatering rate among all the mechanic dewatering equipments used. By transforming sludge-like solid material into cake, the filter press separates water. Moreover, this kind of press is the most widely used dewatering system due to its economical and ease-of-use qualities.

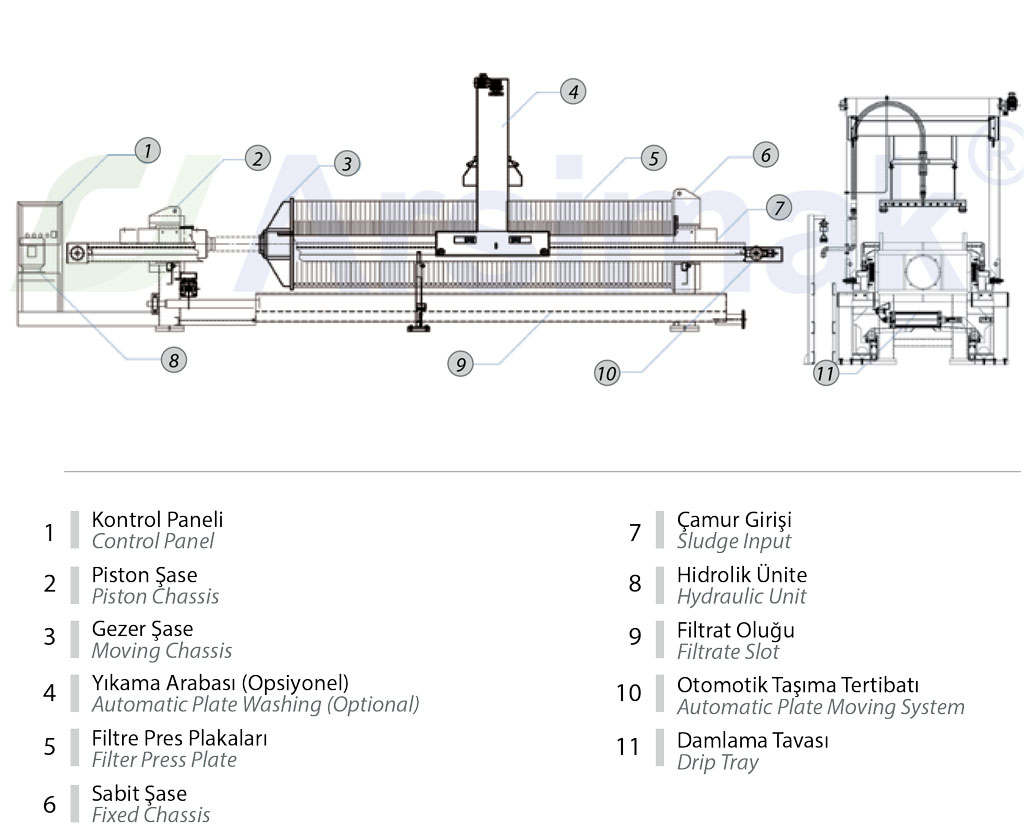

The closure of the Filter press is performed using an automatically or manually activated hydraulic piston.

Belt Filtret Presses Areas Of Usage

Belt Filtret Presses Areas Of Usage

- Food and Beverage Industry

- Industrial Sludges

- Biological Sludge

- Metal Industry

- Mining Industry

- Chemistry Industry

- Pulp and Paper Industry

- Leather Industry

Semi-electrical Hydraulic

In this type, the closing of the plates is performed using a lever present on the hydraulic unit. Once the chosen pressure is reached, again, the mechanic lock on the cylinder is used to continuously maintain the press at the requested pressure.

Automatic plate conveying

After the opening of the press, the plate conveying process is performed by our special conveying apparatus. It has been specially designed for the press. The propulsion is ensured by the hydraulic unit and all the movement transfer elements are in a special receptacle.

Automatic Plate Shaking

The opening process is performed by an accordion-shaped chain. The press, opened at equal intervals, lifts the plates at an adjustable height. This process is performed pneumatically. The number of shaking process repeats is set automatically.

Illuminated Safety Screen

Illuminated safety screens are mounted on the equipment to stop the movement when approaching to unwanted regions of the press during opening and closing.

Belt Wash Station

If wanted, our wash station, allowing a washing operation of the belts with pressurized water up to 100 bars in an adjustable time interval, can be easily mounted on your press. In this case, bouncing membranes will also be installed around the press to prevent plashing. The washing can be automatically activated or push button enhanced.

Plc Controlled Press

Our experimented company offers you all kind of automation services using Plc. Transition Pieces If you want to increase the plate number later, a transition piece can be added during the design. The requested plate number, corresponding to the design, can be thus obtained by dismounting this piece.

DRIP PAN

Dripping can occur during dewatering process of low solid material content or unconditioned sludge. The systematically added drip pan allows to collect liquids and to direct the cake.

PLATE ADDITION IS POSSIBLE

The press capacity can be increased by adding plates.

CONTROLLED PRESS PLC

programming to allow an integrated operation with different systems can be operated.

BELT WASH STATION

This is a high pressure washing system with adjustable time interval that can be added to our equipments. The operation is manually or automatically activated.

ILLUMINATED SAFETY SCREEN

Movements sensors installed in moving parts of the equipment stop the system in potential dangers for the operator and equipment safety during the use of the unit.